From our Mill to your table

In the green heart of Italy

SINCE 1897

ABOUT US

The Origins of our Mill

Everything started back in 1897 when Giovanni Luigi Rinalducci, the owner of a large olive groove, decided that he needed to start producing his own olive oil and then transformed this activity into a real job.

By tradition, in those days, families would help each other in the fields, and olive picking was an occasion of conviviality that ended in the mill, with a bruschetta around the fireplace.

At the end of the 1940s, the family son Emilio returns home after a long imprisonment in a war camp to continue the family tradition. However, he goes a step further. He acquires a cold pressing-extraction plant and starts working for third parties.

TRADITION AND INNOVATION

The Mill Today

In 1998, Emilio inaugurated two extraction plants: a traditional and a continuous extraction one. In 2010, the entire production was transferred to the continuous extraction plant.

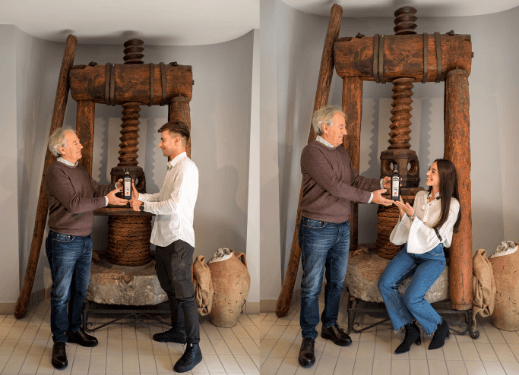

Today, it is Giovanni Rinalducci who is pursuing the family tradition and transmitting his experience, know-how, and passion for his land to his daughter and son.

Recent investments have been directed to develop an oleotourism branch, creating appropriate premises for guided tours and olive oil tasting.

OLEOTURISM

Flavor and territory

An experience in which the discovery and tasting of extra virgin olive oil is combined with visits to places and territories of production, knowledge of culture, traditions.

PRODUCTION CYCLE

Moving with The Times

The ancient machinery

Cold pressing with fiscoli (special mats)

The Continuous cycle plant

Cold extraction plant at monitored temperature

The Production Regulations

Rigorous sensorial and chemical-physical analyses

The Generational Shift

Between tradition and innovation

A New vision for Agriculture

New olive groves

The News in the Supply Chain

“Oleoturism”

Sustainability

The road to sustainability in our company began in 2004, with the purchase of a two-stage decanter, which processes without the addition of water.

The processing waste (vegetation water and pitted pomace) is given to the Umbria Bio Energia Consortium to produce electricity.

The pomace pit is used as fuel for heating.

In February 2023 we installed a photovoltaic system with storage batteries, which makes us self-sufficient for much of the year.

All our materials we use for bottling are recyclable.

KEEP UPDATED